Rutgers Researchers Develop Method with Single-Molecule Precision to Engineer Enzyme ‘Stickiness’

The method aids in optimizing enzymes or proteins ‘stickiness’ for diverse biotechnological applications

Rutgers scientists have developed an analytical toolkit to measure the binding forces of single proteins when they are pulled away from their substrate – such as an enzyme – that will help the development of new nanomaterials, improve biofuel production and global carbon cycling, and identify new and better drug targets, according to a new study.

The study, published in the Proceedings of the National Academy of Sciences, examines the molecular interactions between a carbohydrate binding module (CBM) protein and its binding substrate cellulose. Cellulose, a type of plant fiber polymer made of repeating glucose sugars, can be used to make textiles, cellophane, paperboard and paper, in addition to serving as renewable feedstock to produce biofuels and biochemicals.

Cellulose is the most abundant organic compound on Earth that is naturally decomposed by microorganisms and hence plays a central role in the global carbon cycle. However, scientists still have a limited understanding of how microorganisms like bacteria breakdown cellulose by first anchoring or ‘sticking’ to the substrate surface using carbohydrate binding proteins and enzymes.

According to Rutgers researchers, to engineer more efficient enzymes and microbes that decompose cellulose into sugars for biofuels production such as ethanol, biodiesel, green diesel or biogas, it is necessary to better understand how carbohydrate binding proteins anchor to substrates to engineer better enzymes with optimum ‘stickiness’ that can maximize cellulose decomposition by microbes.

“The binding of proteins and enzymes to complex carbohydrates at the solid-liquid interface is a fundamentally important biological phenomena relevant to plant growth, pathogen-host cell infections, and biofuels production,” said Shishir Chundawat, senior author of the study and an associate professor in the Department of Chemical and Biochemical Engineering at Rutgers. “But such interfacial binding processes are not well understood because of the lack of analytical tools to observe these subtle and short-lived molecular interactions between proteins and carbohydrates like cellulose.”

The methodology describes the researcher’s analytical technique to examine how proteins stick to cellulose surfaces with molecular-level precision, providing insight into the complex mechanisms employed by microbial enzymes during cellulose decomposition.

Chundawat said the toolkit developed at Rutgers can measure single protein-carbohydrate molecule contacts and relevant forces involved with 1 trillionth of newton precision. One newton is equivalent to the minimum force often required to unstick a gecko lizard anchored to a wall or surface.

The research team studied a CBM protein that enables bacterial cells to anchor tightly to cellulose surfaces like a gecko and changed the engineered proteins surface ‘stickiness’ as measured using this new toolkit to enhance cellulose decomposition activity. The findings from the toolkit were in agreement with other experiments and simulations conducted to further explain the underlying molecular rules that are responsible for CBM protein stickiness towards cellulose surfaces.

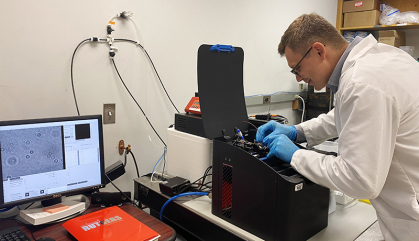

“If particular CBMs can stick to the carbohydrates in specific structural orientations that enhances enzymatic function, traditional methods are not able to differentiate one specific binding orientation from the other necessary to fine-tune protein stickiness for surfaces,” said Markus Hackl, first author of the study who led the development of the toolkit and a doctoral candidate in the Department of Chemical and Biochemical Engineering at Rutgers. “Our method, however, can pick up on those subtle differences in protein stickiness by detecting and measuring the signal from a single protein molecule interaction with cellulose.”

Such a toolkit can help scientists’ study and fine-tune sticky molecular interactions between proteins and carbohydrates, that ultimately aid in the development of better targeting protein-based drugs for improved healthcare or efficient industrial-grade enzymes for low-cost biofuels production.

Development of the toolkit is supported by the National Science Foundation (NSF) Division of Chemical, Bioengineering, Environmental and Transport Systems as part of a Faculty Early Career Development (CAREER) grant awarded by NSF to Chundawat in 2019.

Other Rutgers co-authors on the study include Edward Contrada, Jonathan Ash, Atharv Kulkarni, Ki-Bum Lee, Jinho Yoon, Hyeon-Yeol Cho and researchers from the National Renewable Energy Laboratory (John Yarbrough) and Los Alamos National Laboratory (Cesar López and Sandrasegaram Gnanakaran).